Please click here to access the main AHDB website and other sectors.

- Home

- Carrot storage insulation

Carrot storage insulation

Most UK carrot crops are covered with wheat straw for winter insulation. However, growers are looking for alternatives. This page summarises the findings of two AHDB projects that examined the potential of straw alternatives in theory and in practice.

Why carrot storage insulation is important

A thick layer of straw is a normally used as an insulation material for carrots in situ during the winter months, where ideal storage temperature is between 0–2°C. This can also include a layer of polythene, either above or below the straw.

The aim is to provide insulation against frost damage during the winter and to prevent warming and regrowth in the spring.

However, there are issues with this. Supplies of straw are becoming increasingly volatile and expensive, while there are also concerns over the introduction of weed seeds. Large amounts of straw can also cause nitrogen lock-up for the following crop.

Carrot growers are advised to examine and evaluate alternative options to the current in situ field storage practice.

Recent findings

This information is a summary of findings of two recent AHDB projects, FV398a and FV398b. These examined the potential of alternatives to straw for field storage of carrots in the UK.

Our research found:

- Conventional straw treatments are inefficient in pure insulation terms

- Uncovered crops with exposed crowns and relatively little foliage are at greatest risk of frost damage

- Retention of water in the bottom layers of straw is likely to be providing most of the frost protection. This is the main benefit of using polythene below the straw

- There is no evidence that light exclusion by polythene reduces regrowth, or that is has any impact on crop quality

- Putting polythene over the top instead of underneath straw can reduce straw usage by about two-thirds

- Non-straw materials such as cellulose-fibre insulation (derived from recycled paper) could be viable alternatives, with less potential for nitrogen lock-up and very clean crowns

- Closed-cell PE foam could easily be used as a supplemental layer with straw, if straw is in short supply

- For short-term field storage (i.e. up to Christmas), ensuring crowns are covered with soil and/or one or two layers of polythene may provide adequate protection.

Reports for both research projects are available for download at the bottom of this page.

Is straw best for carrot storage insulation?

Straw is thermally unstable. It is very inefficient in pure insulations terms, but nevertheless it works.

The insulation values of using straw alone are very variable:

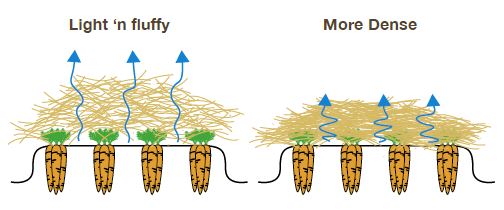

- Straw is typically laid to produce a light fluffy layer

- At typical densities there is a continuum of air space from top to bottom and air pockets are relatively large

- The surface is open, so heat loss is affected by air/wind penetration into the surface layers

- When straw becomes moist/wet, this increases conduction and increases the role of latent heat.

Thermal bridging is another factor that reduces the overall insulation value of a system.

Typically, most of the straw is applied onto the beds, with less straw in the wheelings. The wheelings then act as thermal bridges, which increases the overall heat loss in a field. This is because:

- Heat moves horizontally as well as vertically

- Heat follows the path of least resistance

- Wheelings comprise around 16 per cent of field area – significant heat loss

- Straw filling in the wheelings is a good thing.

Using less straw

Straw alone is inefficient as an insulator due to moisture and the open surface. However, there are things you can do to reduce the amount of straw required:

- Add a polythene layer below - this traps air and is equivalent to about 5cm depth of straw

- Add a polythene layer on top - this keeps it dry and eliminates forced convection, reducing the amount of straw required

Results show that a 5cm layer of dry straw covered with polythene would provide the equivalent insulation to 28cm of uncovered, wet straw, or 20cm of uncovered, dry straw. This could reduce the amount of straw needed by up to 75 per cent.

Alternatives to straw for insulation

A number of alternative insulation materials could provide equivalent or better insulation values to straw, especially if they can be kept dry.

Plant-based, straw or straw-like materials

- This may include XYZ

- These options have similar properties to straw, if they can be applied at sufficient depth and at sufficient bulk density

- There are the same issues with moisture and forced convection, and N lock-up for subsequent crops

- If alternative fibrous materials can be obtained locally at low cost, they may be worth investigating.

Non-straw alternatives

- This may include XYZ

- Non-straw alternatives are likely to be more expensive than straw, so are only feasible if they can be reused several times or if the price of straw further increases. Costs could come down if purchased in bulk quantities

- The cheapest alternative was a layer of PAS100 composted green waste, sandwiched between polythene. However, the amount required (up 200t/ha) would preclude its use due to nitrogen application limits, so it was rejected

- A combination of a layer of composed green waste and a layer of wood shavings could be a less expensive alternative, and would provide long-term slow release of N into soil. However, this would need further study

- Although expensive initially, closed-cell PE (polyethylene) foam may be worthy of further consideration. Typically used in outdoor sleeping mats and as frost protection for freshly laid concrete, its insulation value is unaffected by moisture. It is robust and would have the potential to be reused for several years, and would not require covered storage.

Useful links

Download the factsheet: Insulation materials for carrot field storage

If you would like to read the project reports, grower summary and final reports, use the links below.

FV398a - Carrots: Identifying novel field storage techniques - grower summary

FV398a - Carrots: Identifying novel field storage techniques - final report 2014

FV398b - Practical evaluation of carrot field storage alternatives - grower summary 2017

FV398b - Practical evaluation of carrot field storage alternatives - final report 2017