Please click here to access the main AHDB website and other sectors.

- Home

- Knowledge library

- Steaming options for soil disinfestation

Steaming options for soil disinfestation

Many methods of soil disinfestation using steam have been employed over the years. When done correctly, the procedure has a broad spectrum of activity and efficacy, though treatment to depth can be difficult to achieve.

Soil disinfestation options for cut flower growers

Soil steaming

Soil steaming is the most common and preferred disinfection method in glasshouses where there is multiple cropping of a single species. Benefits include the speed of turnaround, soil can be replanted after just a few days, and there is also no risk of chemical fumes damaging nearby crops. The major disadvantage is cost, as steaming requires high energy use and specialist equipment.

Different methods of steam disinfestation are available. Sheet steaming is the most common, but steam ploughs, vacuum and plate steaming are alternative options.

Mobile steam boilers are increasingly used as a source of steam for soil disinfestation. These can be hired or bought.

Sheet steaming in operation using a mobile steam generator

Courtesy and copyright of ADAS Horticulture.

Sheet steaming

An area of 50–700 m2 of soil can be treated at any one time. Steam is introduced under a heavy-duty plastic sheet, sealed at the edges to prevent heat loss. An additional thermal insulation sheet may also be placed over the plastic sheet and secured in place to improve the efficiency of the process.

To aid steam penetration, the soil should be fairly dry (the optimum moisture content for efficient energy transfer varies with soil type) and cultivated to a coarse tilth. Steam penetrates by displacing the air in the soil, making it difficult to treat wet patches, such as those experienced under guttering.

The time taken to steam the soil depends on the boiler output, distance from the boiler, the soil type and moisture level, and the area to be treated. Temperatures of 60–80°C must be maintained at the required depth for 30 minutes. This makes the process of sheet inflation and full steam penetration time-consuming. Steam penetrates roughly at 4 cm per hour, with 6 hours of steaming required to treat a depth of 25 cm (8 hours to reach 30 cm plus). During steaming, the sheet edges must be monitored to prevent creeping, which may result in a steam blow-out that can be very dangerous.

After steaming is completed, the sheet should be left on for 4–6 hours before removal, making the full process roughly 8–12 hours in duration. Once sufficiently cooled, planting can take place within a few hours. However, soil structure alterations should be left for a few days. Clean footwear should be worn when working on treated soil to prevent re-introducing infections.

Low-pressure sheet steaming

Low-pressure steaming is widely used in the Netherlands and by several UK growers. Steam produced at a lower pressure (0.5 bar rather than above 1.0 bar) enables boiler construction, pipework and valves to be of a lower specification with improved safety. These systems produce wet steam that is passed through a super-heater to dry it, boosting its temperature to 140ºC. Above this temperature, there is a risk that the steaming sheet may melt. The resulting dry, super-heated steam is more effective for soil disinfestation.

What temperature do I need to achieve?

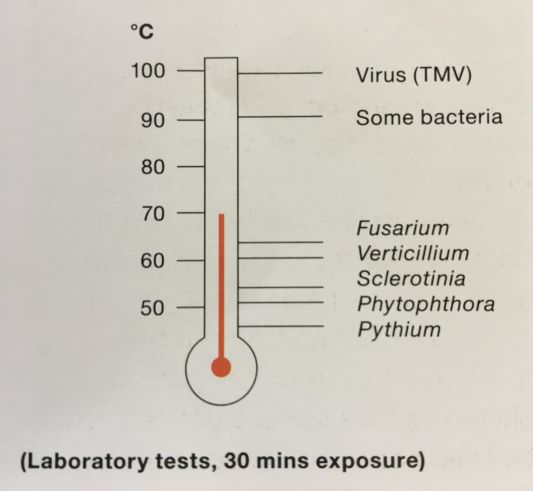

The heat input needed to kill pathogens and pests sucessfully depends on temperature and time. In moist soil, a temperature of 65ºC for 10 minutes is sufficient to kill most pathogens and pests. However, Fusarium oxysporum and Verticillium dahliae are more difficult to kill by heat than species of Pythium and Phytophthora.

A higher temperature (90–100ºC) is needed to treat fungi protected in woody stem bases or roots, such as Fusarium oxysporum within stems, or fungi present as long-term survival structures like sclerotia of Sclerotinia sclerotiorum. Place soil temperature probes at the desired depth to confirm the required temperatures have been achieved. The depth of soil disinfestation achieved depends on the depth of cultivation and pressure under the sheet but rarely exceeds 20–25 cm. This is sufficient for Pythium, Phytophthora, Rhizoctonia and Sclerotinia, but Fusarium and Verticillium can be found at depths down to 30 cm.

The thermal death point of some common soilborne plant pathogens

Manganese toxicity

During the steaming process, some soils release large quantities of manganese which can cause toxicity. Clay and loam soils (with a low pH) are most at risk. This is greatest following the first steaming treatment, declining after subsequent treatments. Manganese levels may continue to rise for some time after steaming has taken place before eventually declining.

Steaming for the minimum time period, or reducing the temperature, will reduce the risk of manganese toxicity. A soil temperature of 75°C will release less manganese than 100°C, and steam-air mixtures may be appropriate in these circumstances. The risk of toxicity can also be much reduced by applications of triple superphosphate and lime after steaming treatment if necessary.

Nitrogen

Soil steaming kills nitrifying bacteria, impacting the nitrogen cycle. Combined with the breakdown of organic nitrogen compounds, this may lead to the release of ammonia and nitrite, and subsequently nitrate. Ammonia and nitrite can give rise to toxicity problems and nitrate may lead to excessive growth. Problems are more likely to occur at high soil pH. As large changes in nutrient levels occur during steaming, analyse soil nutrient levels and adjust any nutrient regime accordingly.

Safety

Although steaming does not involve a plant protection product risk, steam under pressure is potentially very dangerous and only responsible, trained staff should be used. Potential hazards to be aware of are leaking steam mains and ‘blow outs’, where the edge of the steaming sheet is insufficiently sealed/weighted.

Live steam can be dangerous so ensure the necessary health and safety procedures are followed

Courtesy and copyright of ADAS Horticulture.

Heavy-duty plastic sheet, sealed at the edges to prevent heat loss

Copyright of AHDB.

Vacuum steaming, steam plough, self-propelled plate steamer and sandwich steamer

Vacuum steaming

Also known as negative pressure steaming, this process utilises a pump and pipes to remove the air from the soil, creating a negative pressure environment. This effectively ‘sucks’ steam directly into the soil underneath a steaming sheet.

The 6 cm diameter porous pipes are wrapped in a woven plastic mesh to prevent soil blockages. These are buried at around 60 cm depth and 1.6–2.0 m apart, with the ends of tubes connected to a header-tube and vacuum pump at the edge of the glasshouse.

The advantages of vacuum steaming over sheet steaming are thorough steaming to depth and more effective heating, resulting in a shorter steaming period and less fuel use. Vacuum steaming will raise the soil temperature at 33.5 cm depth to over 95°C in less than 4 hours. Vacuum steaming can also be used to treat all soil types.

Steam plough

Unlike sheet steaming, the steam plough injects steam directly into the soil at around 33 cm depth, enabling the soil to become disinfested as the steam naturally rises to the surface. Steam is injected along the small tines of the plough, spaced 23 cm apart in two rows, whilst the plough is winched slowly through the soil (around 10 m per hour). The steam travels along the channels created by the tines. A steaming sheet is drawn behind the plough to reduce the steam escaping from the soil surface. A plough 3.2 m wide allows an area of around 80 m2 to be treated in 7 hours. The direction of the plough is controlled manually to maintain a straight line and to avoid collisions with the glasshouse architecture.

Steam ploughs use less fuel and have improved activity at depth compared with sheet steaming. However, they require constant attendance, and there is a low treatment rate. Care must be taken to ensure the soil surface receives sufficient steam to kill target organisms.

Steam plough trials in Norfolk demonstrated that soil became raised to over 95°C for over 1 hour at 3.5, 13.5 and 23.5 cm depth, and to over 80°C for 30 minutes at 33.5 cm depth and this was sufficient to eliminate Fusarium oxysporum from almost all pieces of buried stem and root pieces of stock. This process was also effective in killing sclerotia of Sclerotinia sclerotiorum.

A comparison of sheet steaming, vacuum steaming, and the steam plough can be found in Table 2.

Table 2. Summary of some key characteristics of steaming methods*

| Method | Effectiveness of treatment | Fuel use **(m3 gas/m2) | Usual rate of treatment in UK |

| Sheet steaming | × | 7 | 50–700 m2 in 8–12 hrs |

| Vacuum steaming | ××× | 4 | 125 m2 in 4 hrs |

| Steam plough | ×× | 3-4 | 80 m2 in 7 hrs |

*Adapted from information from the Netherlands

**To achieve 70°C for > 30 minutes

The steam plough ensures thorough treatment at depth

Courtesy and copyright of ADAS Horticulture.

Self-propelled plate steamer

Self-propelled steam generators inject steam under pressure from a plate down to around 7 cm soil depth. Trials in the UK showed good control of Pythium to 5 cm depth (HDC/AHDB project FV 229), and work in Norway showed that at 10 cm depth, a temperature of 70°C was attained in 6–9 minutes, resulting in good control of weeds.

This method of steaming is designed for use outdoors, especially for short-term crops where the major concern is weeds. It is most suited for intensively cropped land where the depth of treatment is not a major concern.

Self-propelled plate steamer for field-grown crops

Copyright of AHDB.

Sandwich steamer

Sandwich steaming injects steam 25 cm into the soil through hollow pins with multiple exit holes. This method is faster and more efficient than plate steaming, achieving 85°C+ temperatures quickly and evenly. Models claim 35% reductions in energy compared with sheet steaming.

Sandwich steamer on caterpillar vehicle (note pins just visible on the underside of the plate)

Copyright of AHDB.

Perforated pipe wrapped in woven mesh is buried at 60 cm depth to enable vacuum steaming

Courtesy and copyright of ADAS Horticulture.

Authors

Author(s) – Dave Kaye and Erika Wedgwood. ADAS Horticulture.

Original author(s) – Tim O’Neill and Kim Parker. ADAS Horticulture.

Webpage content correct as of June 2021.

Topics:

Sectors:

Tags: